Summary:Standard metal access panels are typically made from various materials, each offering different benefits. Here are the common materials used:

1. Galv......

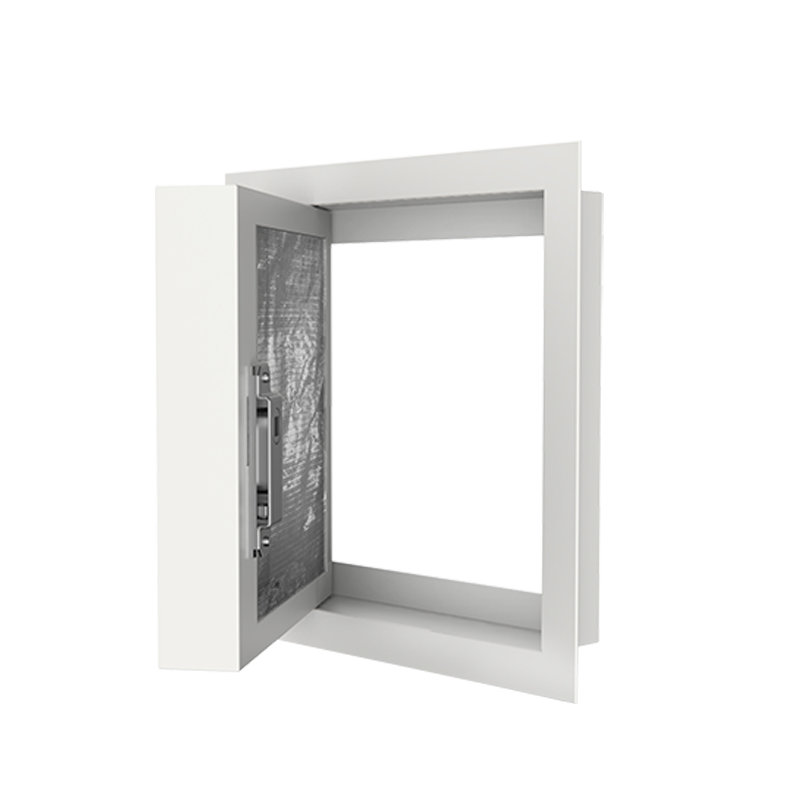

Standard metal access panels are typically made from various materials, each offering different benefits. Here are the common materials used:

1. Galvanized Steel

- Description: Coated with zinc to prevent rust and corrosion.

- Benefits: Durable, strong, and resistant to environmental factors. Commonly used in commercial applications.

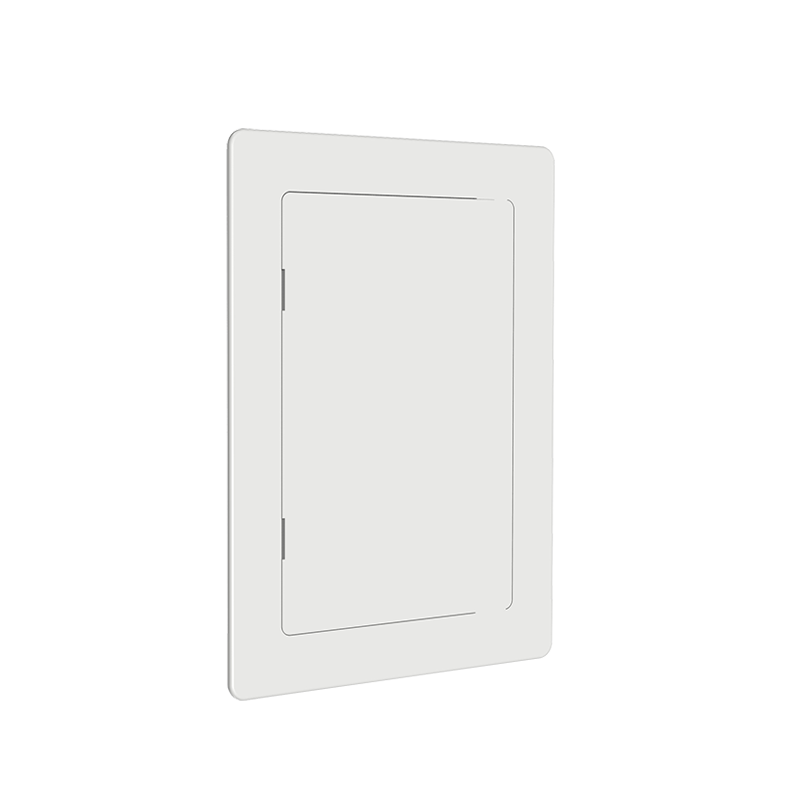

2. Aluminum

- Description: Lightweight metal that is resistant to corrosion.

- Benefits: Easy to handle and install, making it suitable for various applications, including residential and commercial.

3. Stainless Steel

- Description: An alloy known for its corrosion resistance and strength.

- Benefits: Ideal for high-moisture or corrosive environments, such as kitchens or laboratories. Offers a sleek appearance but is generally more expensive.

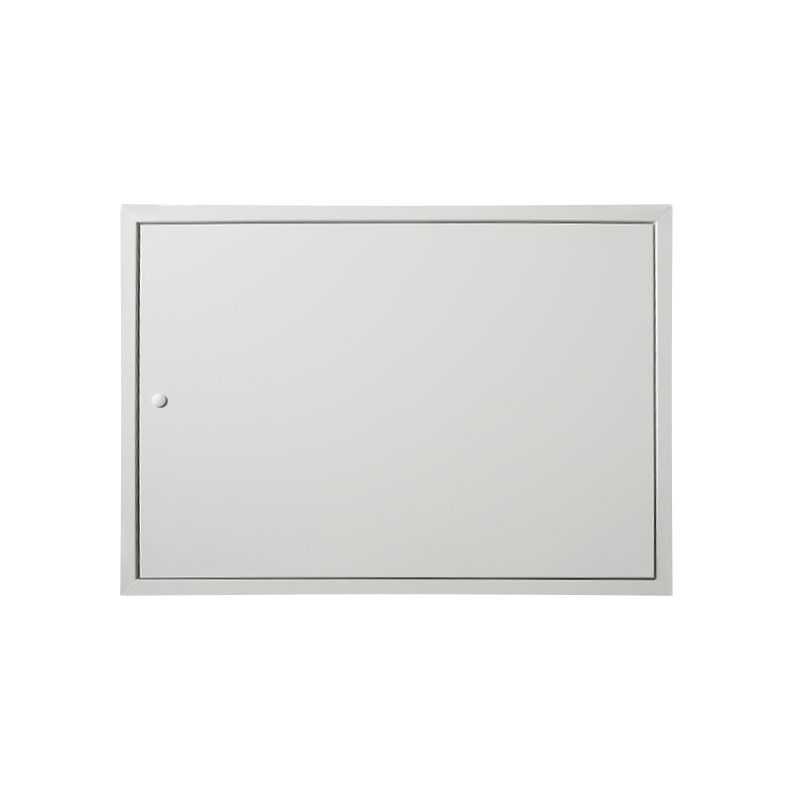

4. Sheet Metal (Mild Steel)

- Description: A common type of metal used, often treated or painted for protection.

- Benefits: Cost-effective and versatile, but requires additional coatings to prevent rust.

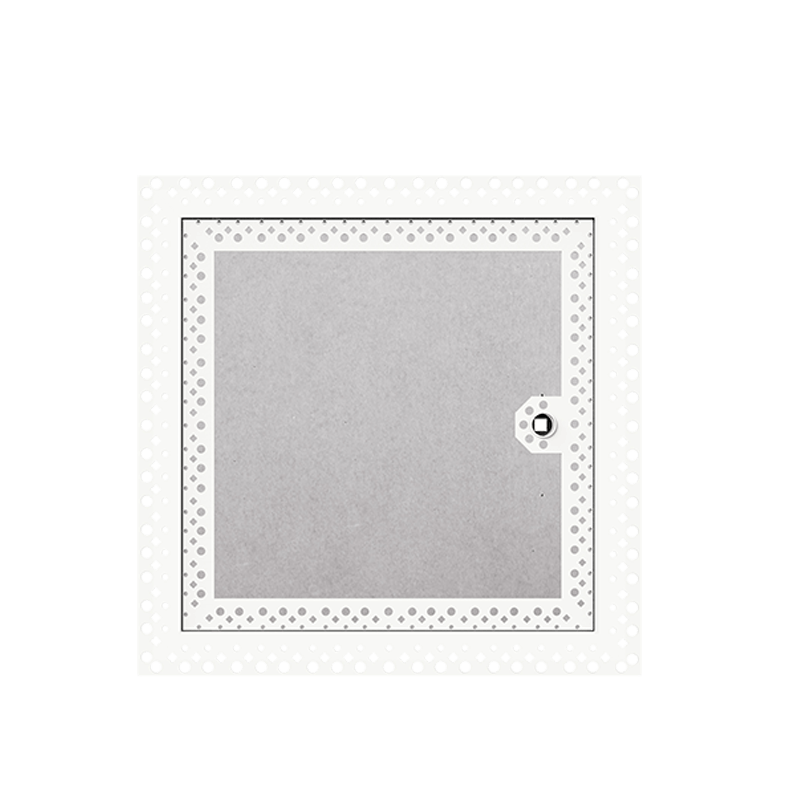

5. Plastic Coated Panels

- Description: Metal panels coated with a plastic finish for added durability.

- Benefits: Provides additional protection against corrosion and wear, while also being aesthetically pleasing.

Conclusion

When selecting a standard metal access panel, consider the environment in which it will be installed, the required durability, and any aesthetic preferences. Each material has its advantages, making them suitable for different applications.

English

English 简体中文

简体中文 France

France España

España العربية

العربية