When choosing materials for moisture resistance, consider the following options:

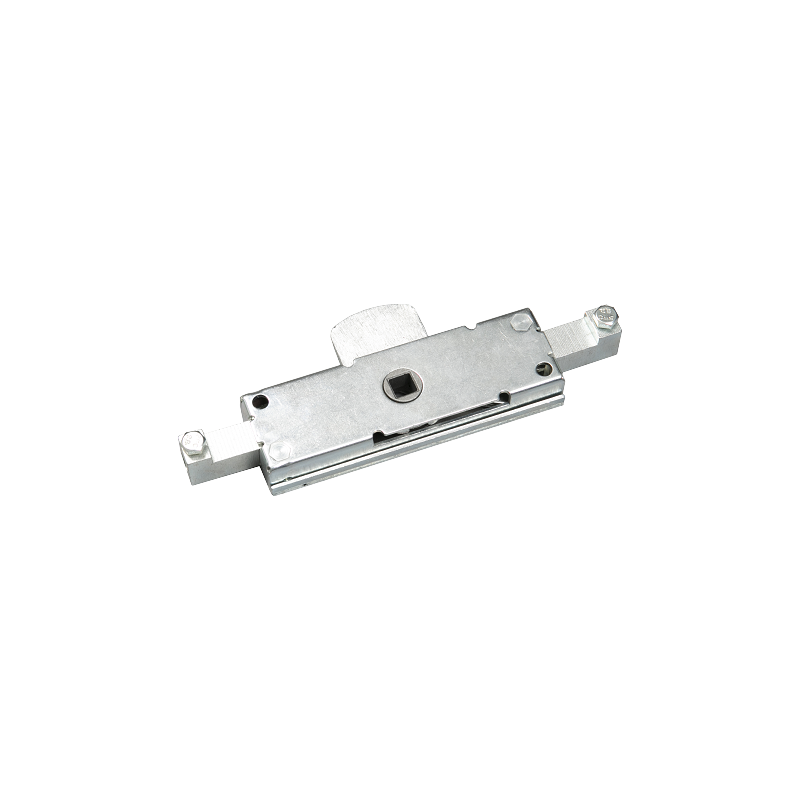

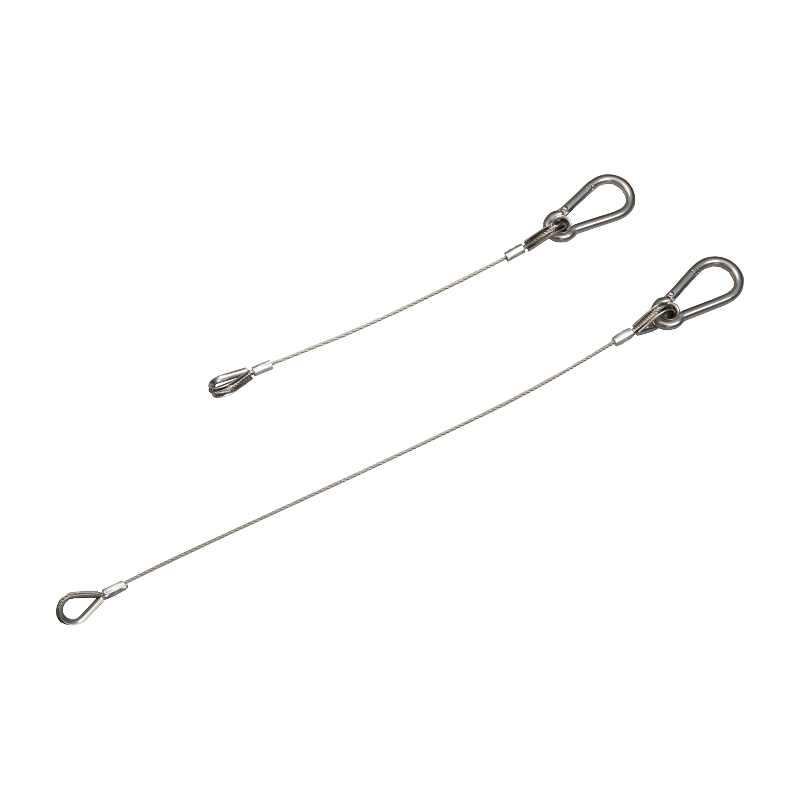

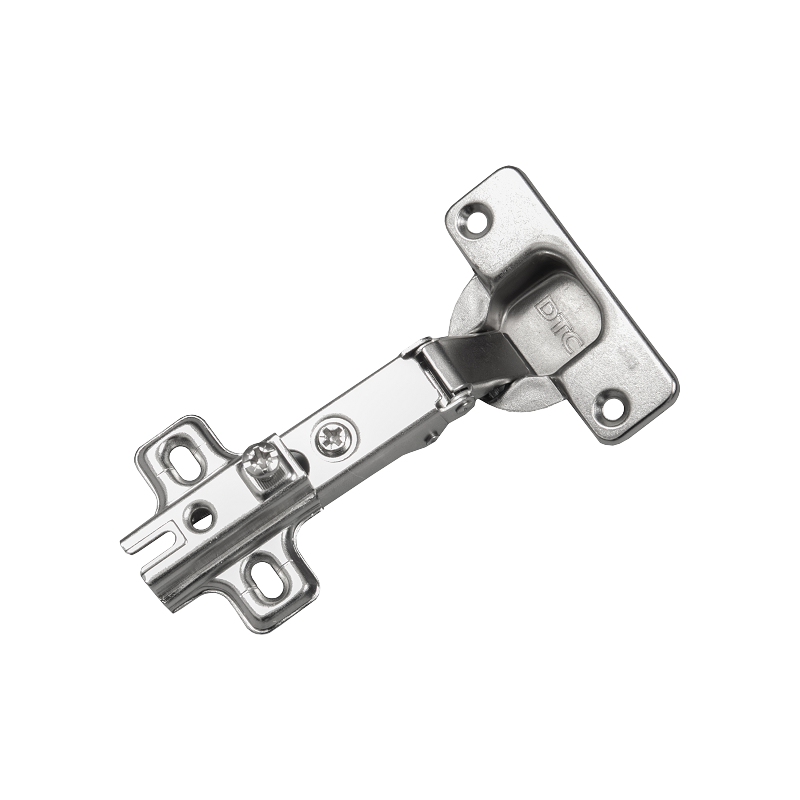

1. Stainless Steel

- Excellent corrosion resistance and durability, making it ideal for humid environments.

2. Galvanized Steel

- Steel coated with zinc to prevent rust, suitable for areas with exposure to moisture.

3. Aluminum

- Lightweight and naturally resistant to corrosion. It’s a good option for areas with high humidity.

4. Plastic (PVC or ABS)

- Highly resistant to moisture and does not corrode. Ideal for applications where water exposure is frequent.

5. Fiberglass

- Strong and moisture-resistant, fiberglass panels can withstand harsh conditions without deteriorating.

6. Composite Materials

- Made from a combination of materials, composites can be designed to resist moisture and provide durability.

7. Water-Resistant Coatings

- Applying a water-resistant coating to wood or other materials can enhance their moisture resistance.

8. Concrete

- When properly sealed, concrete can be moisture-resistant and is suitable for basements or exterior applications.

Key Considerations:

- Sealing and Finishing: Ensure that any seams or joints are properly sealed to prevent moisture ingress.

- Maintenance: Regular maintenance and inspections can help prolong the life of moisture-resistant materials.

Choosing the right material based on these properties will help ensure durability and performance in moisture-prone environments.

English

English 简体中文

简体中文 France

France España

España العربية

العربية