For many builders, one of the most time-consuming parts of their job is setting up the fire exit and escape systems in a commercial building. The main problem is that the systems must be installed in such a way that they do not pose any hazard to those working below them. Often this involves unscrewing or pulling down walls and crawling through shafts to reach them. Fire exits and escape systems require careful planning, especially when large, multi-story buildings are involved.

Portable access panels eliminate the requirement to cut through ceilings, walls, and floors while navigating through tight hidden spaces. Instead of ripping through drywall or flaking tile, they facilitate easy access to firefighting equipment, plumbing, electrical sections, or other important objects in buried underground spaces. Depending on the structure of the access panel, it may also feature locking mechanisms to prevent unauthorised entry. The panel may include a combination door and window, allowing for easy panes of glass for ventilation and light. In addition to permitting easy vision into a space, access panels can be installed above ground to provide for controlled entry.

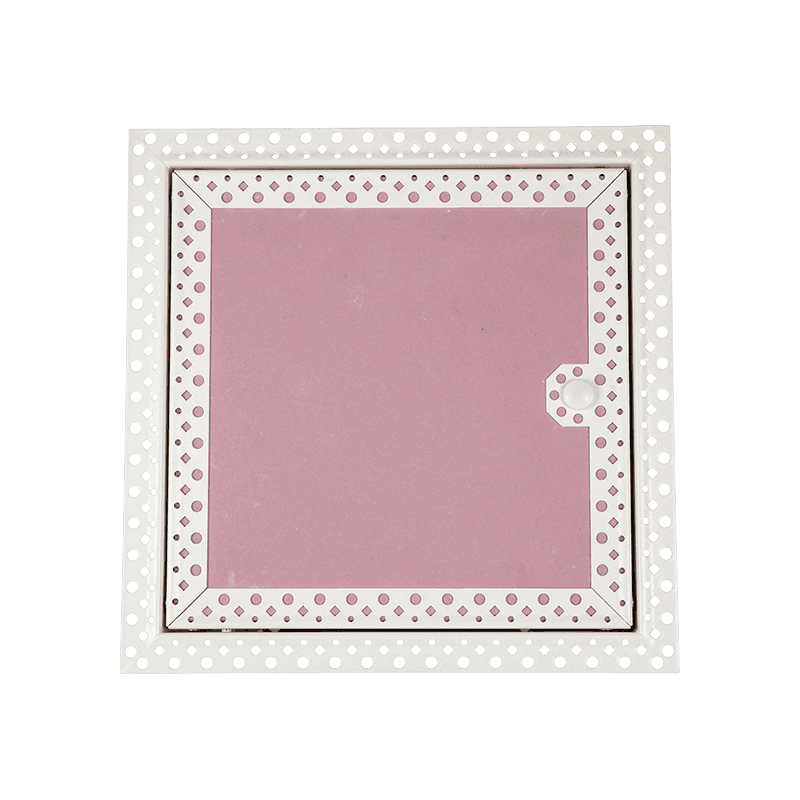

A fire recessed drywall access panel may be used to access a wide variety of spaces in a room. A good one should have a minimum of two doors - one to the outside and one to the inside. When installing the panels, be sure to install them recessed slightly below the surface of the ceiling and walls, so as not to break the frames or damage electrical wiring.

To help contractors avoid the hassle and expense of moving large pieces of sheetrock and then the labor of reassembling them once they are in place, many now include a "ping-up" joint that screws together the two parts at the same time. This prevents the "ping-up" joint from becoming loose and allows easy access when necessary. An access panel is normally affixed to the exterior surface with screws.

Many modern buildings contain insulation or windows, which require an insulated door. A quality access door should be rated for the type of insulation present on the door frame. The material of the door should match the exterior finish if possible. If not, it can compromise the structural integrity of the doors.

Some access doors feature double panes of glass for added fire protection. Often these are located near windows or in rooms where there is a requirement for additional protection from heat. However, if there is no window to accommodate the double paned glass panel, then a more economical alternative is to use a sheet metal door with only one pane. These are not normally rated by NACH recommended ratings, so it is important to check this information with the building manufacturer. It is also important to ensure that the fire protection level is sufficient to meet local building regulations.

There are several other features to consider when selecting a suitable panel for an access door. Firstly, the width of the door must match the width of the frame and any other sliding doors in close proximity to it. Next, the panel must be rated for the kind of weight it is required to carry. This may be affected by the fact that the door is to open and close in a wide variety of ways, including opening and closing by remote control. Finally, many different types of panels allow a user to select key locks, either electronic or manual.

Other features to look for when purchasing a new Access Panel include fire protection and water resistance. Some panels are made from materials which will resist fire and are non-rated by the Joint Commission International (J CI). Other access panels will be rated either by NACH or by the EPC. A good quality non-rated drywall access panel can offer fire and smoke resistance up to a 2 hour indoor fire. This level of protection is usually only available from well rated access panels.